top of page

AIRPLANE CABINET

Structural Optimization

During my summer internship at Dassault Falcon Jet, I worked on optimizing the storage space, internal structure and weight of a cabinet located in the middle of the Falcon 8X cabin, right underneath the emergency exit. The modifications increased the storage volume by 1.7 liters without increasing the size of the cabinet, reduced tenon and mortise joints by 33% decreasing manufacturing time, reduced the number of attachments to the basic structure of the aircraft from 14 to 12, decreased manufacturing costs by using cheaper honeycomb panels without compromising structural integrity, and reduced the overall weight of the cabinet by 2.85Kg (6.28 lbs).

Airplane Cabinet: About

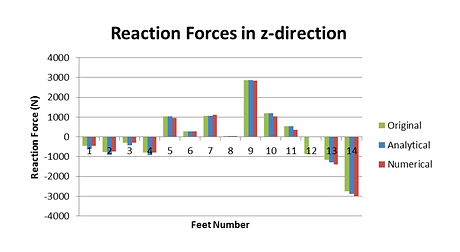

A structural model of the Mid Run Cabinet was created on CATIA and imported into ANSYS Structural to perform FEA. It was determined that the cabinet panels were not the critical part of the structure, but the basic structure of the plane where the feet are attached (the floor beam and the floor panel). Therefore, the interface loads between the cabinet and the airplane floor were analyzed.

Airplane Cabinet: About

The predictions of the interface loads done with an analytical method (hand calculated) were very similar to those obtain by the FEA model. It can also be seen that the interface loads for the feet around the foot removed have an increment on magnitude, but it was determine that it was not critical for the structure.

Airplane Cabinet: About

bottom of page